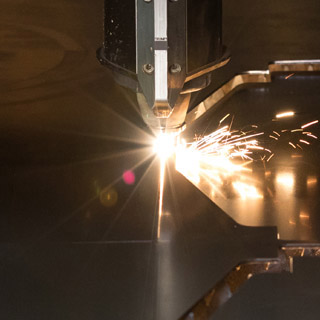

Laser cutting in Hungary with export experience

Our company is located in the South from Budapest, an economically and industrially frequented place in Pest county. Our company’s experience and the knowledge of the modern technology guarantee the needs of the individual or the series production. Our team made-up of highly qualified specialist. We perform our work well-oraginzed by the dead line, with complience of the quality standards and on reasonable prices.

Sari Metal Ltd deals with lasercutting of carbonsteel, stainlesssteel and aluminum materials. Our cutting -edge lasercutting machines are perfectly suited for cutting metal parts from flat panel boards. Whether it is a small or large number of parts, our Trumpf laser cutting machines adapt to different market demands and expectations. Optimal designed production management system enables the introduction of work in shifts that will result in accurate and rapid compliance with deadlines!

We pursue to be the suppliers of sheet metal to such companies which imagine the future with flexible production and reasonable prices.

Laser cutting parameters:

- Carbon steel: 0.5mm-25mm

- Stainless steel: 0.5mm-20mm

- Aluminum: 0.5mm-20mm

- Galvanized steel: 0.5mm-3.0mm

- Cutting table dimensions: 1500x3000 mm

- Trumpf 3050 - 6KW

- Trumpf 5030 - 6KW

Online quotation For more information contact our collegaue

Cost effective laser cutting in Hungary

Thanks to the stunningly fast positioning and cutting speed and innovative manufacturing preparation and the computerized cutting path of our laser cutting machines, we can create a more efficient, faster, and lower cost production.

Cost effective and Clear cutting

Burr and drossless edges.CO2 laser cutting with nitric assisting allows smooth, clean cutting of aluminum stainless steels.

Laser cutting = Perfect detail

Laser cutting greatly simplifies design and manufacturing processes. The focused laser beam creates perfectly accurate details with very sharp corners. The process is non-contact so the thinnest plates can be cut without damages.